Christmas Porter 2013 Brew Morning

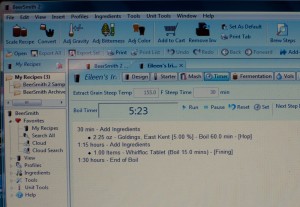

This is a chocolate mint porter. Brew Day started bright and early on Sunday. I still struggled with the mash. I need to look carefully at how I’m building the recipe in Beersmith (actually, this an interpretation of a Jamil Robust Porter recipe from a user on Beersmithrecipes.com that I modified for my purposes). I believe I’m using too much water. The starches are being converted and giving the right gravity, but by the time I sparge, it dilutes down too far. I had 1-2 gallons of wort that never made it into the boiling pot. It wasn’t too far off, though…I think it’ll work fine for this brew.

Christmas Porter 2013 Boil

The 90-minute boil went fine, although I did have a bit of foam spill over at the beginning of the boil, making a bit of a mess on the outside of the pot. It turned into a dark, dark brown wort with a nice tan “head” that I hope carries over to the finished product.

I fell a little short on the hops (didn’t have the surplus I thought I had), but I want the sweetness of the chocolate to come through, anyway.

Christmas Porter 2013 adding mint

I ended up with about 1/2 ounce of fresh mint from our garden. This worked very well in the Mojito Beer, so I have high hopes for it here. I only gave it about 10 minutes in the boil… looking for more aroma than flavor. I’m really hoping for a chocolate-mint candy impression in the finished beer. If it needs more mint after primary fermentation, I can add more to the secondary. That’s also when I plan to add the cacao nibs.

Christmas Porter 2013 chocolate

However, I added about 3 ounces of this wonderful dark chocolate I found at BevMo in Lodi. Yum…

BJCP style guide

Recipe Details

| Batch Size |

Boil Time |

IBU |

SRM |

Est. OG |

Est. FG |

ABV |

| 6 gal |

90 min |

38.0 IBUs |

36.0 SRM |

1.061 |

1.016 |

6.0 % |

|

Actuals |

1.06 |

1.01 |

6.6 % |

Style Details

| Name |

Cat. |

OG Range |

FG Range |

IBU |

SRM |

Carb |

ABV |

| Robust Porter |

12 B |

1.048 - 1.065 |

1.012 - 1.016 |

25 - 50 |

22 - 35 |

1.8 - 2.5 |

4.8 - 6.5 % |

Fermentables

| Name |

Amount |

% |

| Simpsons Ale - Golden Promise |

10.878 lbs |

75 |

| Bestmaltz Munich Light |

1.595 lbs |

11 |

| Joe White/Maltcraft Chocolate |

13.92 oz |

6 |

| Simpsons Black Malt |

9.28 oz |

4 |

| Weyermann® Carapils®/ Carafoam® |

9.28 oz |

4 |

Hops

| Name |

Amount |

Time |

Use |

Form |

Alpha % |

| Goldings, East Kent |

1.4 oz |

60 min |

Boil |

Pellet |

5.4 |

| Fuggles |

0.8 oz |

60 min |

Boil |

Pellet |

5 |

| Fuggles |

0.89 oz |

30 min |

Boil |

Pellet |

5 |

| Fuggles |

0.42 oz |

0 min |

Boil |

Pellet |

5 |

| Goldings, East Kent |

0.42 oz |

0 min |

Boil |

Pellet |

5.4 |

Miscs

| Name |

Amount |

Time |

Use |

Type |

| Whirlfloc Tablet |

1.00 Items |

15 min |

Boil |

Fining |

| Fresh Mint Leaves |

2.00 oz |

10 min |

Boil |

Herb |

| Chocolate (Dark) |

4.00 oz |

5 min |

Boil |

Spice |

| Cacao Nibs |

4.00 oz |

0 min |

Secondary |

Spice |

Yeast

| Name |

Lab |

Attenuation |

Temperature |

| British Ale Yeast (1098) |

Wyeast Labs |

74% |

64°F - 72°F |

Mash

| Step |

Temperature |

Time |

| Saccharification |

154.4°F |

60 min |

| Mash Out |

168.8°F |

10 min |

Notes

| From Beersmith recipes Regan Dillion Porter (Jamil BYO). |

![_AMT4781 [1600x1200]](http://commanderdata.com/3Acres/wp-content/uploads/2013/09/AMT4781-1600x1200-300x199.jpg)